What is Manufacturing Technology?

Any activities involved in transforming raw materials into finished products are part of the manufacturing process. This might be accomplished through the use of labor, machinery, chemicals, formulation methods, or biological processes, to add value to a raw material before selling it. But, what is manufacturing technology?

In simple terms, any technology that shapes or influences the manufacturing process is a form of manufacturing technology, which provides the tools that enable the production of all manufactured goods.

The tools of production include machine tools, related equipment, and their accessories and tooling. Machine tools are usually non-portable, power-driven manufacturing machines and systems used in performing specific actions on various materials to produce marketable products or components. Equipment and technologies relevant to this description would include Computer Aided Design (CAD), Computer Aided Manufacturing (CAM), and the assembly and testing systems needed to produce a sub-assembly or finished product.

Among the most commonly used manufacturing technologies are:

Software-Based Systems: These include Computer Aided Design (CAD), Computer Aided Manufacturing (CAM), Computer Numerical Control (CNC), Direct Numerical Control (DNC), Programmable Logic Control (PLC), Numerical Control (NC), systems integration software, and software for process optimization.

Material Removal Tools And Processes: Drilling, milling, turning, grinding, tapping, sawing, broaching, electrical discharge machines (EDM), water jet cutting and laser process equipment, are all examples.

Material Forming Equipment And Processes: e.g., cold and hot forming equipment, stamping, bending, joining, shearing, presses, and hydro-forming.

Work Holders: Systems for holding components in place, such as clamps, blocks, chucks, tooling columns, angle plates, and fixtures.

Tooling Systems: These include drills, taps, punches, dies, reamers, boring bars, and grinding wheels.

Material Handling Systems: Conveyors, pallet changers, die handling equipment, bar feed equipment, automated wire guided vehicles, and robots are all in this class.

Automated Systems: Among this class of manufacturing technology are assembly systems, transfer machines, and Flexible Manufacturing Systems (FMS).

Additive Processes: These include 3D printing, laser sintering, and rapid prototyping equipment.

Several types of manufacturing systems are made possible through the application of different forms of manufacturing technology. Among the most widely used are the following.

Computer Numerical Control (CNC)

Computer Numerical Control or CNC machining is a manufacturing process in which special computer software programs govern the activities of factory tools and machinery. Using CNC, it’s possible to control a range of complex machinery, including grinders, lathes, mills, and routers. CNC machining enables manufacturers to use single set of configuration triggers to perform three-dimensional cutting tasks.

Computer Numerical Control or CNC machining is a manufacturing process in which special computer software programs govern the activities of factory tools and machinery. Using CNC, it’s possible to control a range of complex machinery, including grinders, lathes, mills, and routers. CNC machining enables manufacturers to use single set of configuration triggers to perform three-dimensional cutting tasks.

Programs for CNC machines are fed to computers though small keyboards, using a standard language known as G-code. This code is written to control the various behaviors of a particular machine, such as the speed, feed rate, and coordination. Newer prompts can be added to pre-existing programs through revised code.

When a CNC system is run, the software program is configured with a set of desired cuts, which are relayed to the relevant tools and machinery that carry out the designated tasks, in a similar manner to a robot.

Computer-Controlled Production

Computer Integrated Manufacturing or CIM is a system that uses computers to control an entire production process. It’s a technique commonly employed in factories whose management are looking to automate design, accounting, purchasing, distribution, inventory control, and other business functions.

Typically, a central administrative console links all of these disparate functions, to facilitate efficient materials handling and management, while simultaneously delivering direct control and monitoring of all operations.

CIM is an advanced manufacturing process that often includes the following:

- Computer-Aided Design (CAD)

- The manufacture of prototypes

- Efficiency calculations for costs and materials handling

- Computer-aided manufacturing of the products

- Production line assembly using robots

- Quality control measures

- Automatic distribution of products

- Automatic updating of production logs, financial data, and bills

By streamlining production processes, computer integrated manufacturing reduces the costs of direct and indirect labor, reduces downtime, maintains correct inventory levels, and improves efficiency.

Flexible Manufacturing

A flexible manufacturing system or FMS is a means of production that can easily adapt to changes in the kind of products being made, and the amount of goods produced. By configuring the machines and computerized systems of an FMS setup, organizations can manufacture a range of different components, and cater for changing levels of production.

In this way, a flexible manufacturing system can improve the organization’s efficiency, and lower the company’s production costs. Manufacturers can also use an FMS to implement a “make-to-order” policy, which allows customers to customize the products that they want.

A typical flexible manufacturing system might include a set of interconnected workstations with processing terminals that govern the complete life cycle for creating a product: loading, unloading, machining and assembly, storage, quality testing, and data processing. This can result in considerable capital costs for setting up, and require the hiring of skilled technicians to keep the system running.

Producing Cutting-Edge Tech

The high tech manufacturing sector produces cutting-edge technology, and is characterized by a high degree of complexity, stiff competition, and high costs. Products range from computers to jet engines, component parts (circuit boards, semiconductors, and the like) and also the complex machines that manufacture all of these components and finished products.

The high tech manufacturing sector produces cutting-edge technology, and is characterized by a high degree of complexity, stiff competition, and high costs. Products range from computers to jet engines, component parts (circuit boards, semiconductors, and the like) and also the complex machines that manufacture all of these components and finished products.

The cost and complexity challenges fa

cing high tech manufacturers are attributable to a number of factors, including unpredictable cycles of supply and demand, long manufacturing lead times for critical component parts, difficulties in obtaining raw materials, and complex production processes.

High-tech manufacturers must therefore have efficient supply chains, and the agility to enable them to deliver for customers on time and in full (OTIF), while keeping their costs and inventory levels down.

Applied Engineering For Industry

Manufacturing engineering technology is an applied engineering discipline that seeks improved ways of making products. The manufacturing engineering technology field takes a methodical and scientific approach with an emphasis on upholding quality standards, reducing cycle times, and keeping costs at reasonable levels.

In practice, the discipline takes a hands-on approach to problem solving, rather than relying on complex mathematical analysis. Manufacturing engineering technologists typically work with many departments in an enterprise, ranging from inventory control to sales.

Industry-Specific Press

As with most specialist fields these days, there exist web sites and literature dedicated specifically to the usage of technology in the industrial sphere.

Manufacturing Technology Insights for example, is a print magazine that offers a knowledge base and networks for key decision makers in the manufacturing arena. The publication covers prevailing trends, consumer behavior, and the several technology solutions which are disrupting the industry. The magazine also advises manufacturing firms on the connectivity infrastructure and digital tools that can provide an insight into production levels, inventory, available production capacity, quality levels, and order status from all of their suppliers.

Different types of Manufacturing Technology

Though commonly associated with grime and metalwork, the manufacturing industry spans diverse sectors including food production, textile product mills, apparel making, wood product manufacturing, chemical manufacturing, and the manufacture of computer and electronic products. Each of these different types of manufacturing process use characteristic tools, techniques, and technologies.

Manufacturing Technology

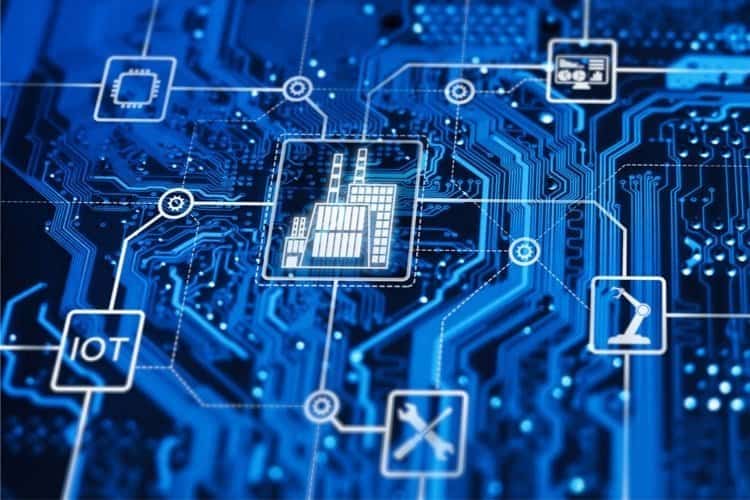

Manufacturing technology is a fairly broad term referring to a number of tools, systems, and methods of science, production, and engineering to assist in industrial production and various manufacturing processes. In the modern context, many of the different types of manufacturing technology relate directly to the Fourth Industrial Revolution, or “Industry 4.0”, and deal with innovations such as automation, data exchange, digital technology, artificial intelligence, machine learning, and the Internet of Things or IoT.

In this regard, some of the more prominent types of manufacturing technology include:

Smart Factories: These are highly digitized manufacturing environments with devices and sensors linked via network connectivity. Using automation and self-optimization, these machines and systems can learn and adapt to situations to develop increased productivity. While able to produce goods on a large scale, smart factories can also facilitate processes such as planning, supply chain logistics, and product development.

Cyber-Physical Systems: These systems integrate computer, networking, and physical processes, allowing embedded computing technologies to control and monitor processes in real time. The computer system monitors the process and identifies areas where change is required, and the physical system reacts accordingly.

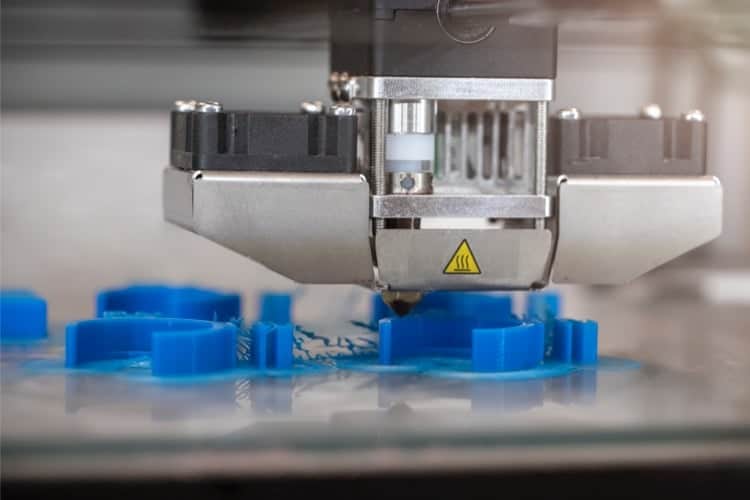

Additive Manufacturing: This blanket term describes a range of technologies and computer controlled processes in which three-dimensional objects can be created by materials deposited in layers. Objects can be fabricated without the use of machining or other techniques, resulting in less surplus material.

Augmented Reality (AR) And Virtual Reality (VR): Augmented reality or AR technology displays digital content as an overlay on the real world, while virtual reality (VR) enables the digital creation of complete environments. This allows for the visualization of products or the superimposing of data or plans onto physical components and machinery.

Robotics And Automation: Robotic process automation (RPA) allows repetitive tasks to be performed practically indefinitely, with precision, high efficiency, and very little error. Robotic devices can operate in conditions or environments inaccessible to humans, implementing processes like laser cutting and additive manufacturing which rely on computer numerical control to efficiently and remotely create products.

Manufacturing Systems

A manufacturing or production system consists of any of the methods used in industry to create goods and services from various resources. Such systems are “transformation processes,” in that they transform resources into useful goods and services.

There are different types of manufacturing systems, whose usage will depend on what an organization wishes to manufacture, how they want to manufacture it, how big the enterprise is, and various other factors. The most common systems in use today include:

Continuous Manufacturing System: The classic mass production scenario, in which a product moves along an assembly line, with workers performing various specialized actions to assemble the product at stations along the way. This allows for higher output and lower unit costs, but requires a large capital investment in labor and machinery.

Continuous Manufacturing System: The classic mass production scenario, in which a product moves along an assembly line, with workers performing various specialized actions to assemble the product at stations along the way. This allows for higher output and lower unit costs, but requires a large capital investment in labor and machinery.

Intermittent Manufacturing System: Here, the manufacturer produces multiple identical items at the same time, using a system with little or no allowance for customization, in which the products must be standardized. Intermittent manufacturing is usually most effective for low-volume or limited production runs.

Flexible Manufacturing System: In a bid to make the organization more adaptable to changing marketplace conditions, a flexible manufacturing system enables companies to invest in several machines that they can easily reconfigure to make a lot of products in a short period of time. Robots or other automated devices to replace or augment human labor are characteristic features of these systems.

Custom Manufacturing System: In a custom manufacturing system, each product is made by hand or by a single operator using a machine specially designed for this purpose. Companies typically use custom manufacturing for very specific product lines.

Manufacturing Processes

Besides the specific industry vertical, different types of manufacturing organizations will select their production process based on a number of factors, such as consumer demand, the manufacturing technique for their final product, and available resources. Each process is different, and they all have their advantages when completing a certain task.

There are several types of manufacturing process, which may be summarized as follows:

Repetitive Manufacturing: Organizations would typically use repetitive manufacturing for repeated production that commits to a certain production rate. Dedicated production lines for repetitive manufacturing processes can produce the same item or a variety of items, on a 24/7, year round basis. Setup requirements are often minimal, so operating speeds can be increased or decreased to meet customer demands or changing requirements.

Repetitive Manufacturing: Organizations would typically use repetitive manufacturing for repeated production that commits to a certain production rate. Dedicated production lines for repetitive manufacturing processes can produce the same item or a variety of items, on a 24/7, year round basis. Setup requirements are often minimal, so operating speeds can be increased or decreased to meet customer demands or changing requirements.

Discrete Manufacturing: For types of manufacturing that require a variation of setups and changeover frequencies, discrete manufacturing assembly or production lines enable organizations to adapt to factors based on whether the required products are similar in design, or significantly different.

Job Shop Manufacturing: This process produces smaller batches of custom products, which can be made-to-order (MTO) or made-to-stock (MTS). As a result, job shop manufacturing uses production areas, rather than assembly lines. Workstations may be organized to make one version of a custom product, or more.

Continuous Manufacturing: Also known as process manufacturing, this is similar to repetitive manufacturing, in being a 24/7 operation. Raw materials are typically gases, liquids, powders, slurries, or granules. Product designs are generally similar, unless the disciplines required to create a final product or production process are more diverse.

Batch Manufacturing: Another form of process manufacturing, which shares similarities with the discrete and job shop processes. Batch processes are continuous in nature, and once a batch is completed, the equipment is cleaned, ready to produce the next batch. Ingredients for batch manufacturing are similar to those for continuous manufacture, but the production processes tend to be more diverse.

Additive Manufacturing: A set of technologies that enable products to be produced from various composites and materials, rather than the traditional methods of physical labor or automation. The most well-known form is 3D printing, which assembles components in layers of material.

Beyond 3D Printing

As we observed in the previous section, 3D printing is just one in an array of different types of additive manufacturing. Several individual additive processes exist, each varying in the way they build up material layers, and in the substances and hardware that they use.

A standards organization known as the American Society for Testing and Materials (ASTM) classifies the various additive technologies into seven categories:

VAT Photopolymerisation

This method uses a liquid plastic resin or photopolymer, which provides the feed material for building up a model in layers.

Material Jetting

Here, a jet of material is projected onto a platform in a continuous stream or in calibrated drops, in a way similar to the workings of a two dimensional ink jet printer.

Binder Jetting

This additive process uses a structural material in powdered form, and a binding medium, which is generally a liquid. In binder jetting, the machine’s print head moves laterally, depositing a layer of build material then one of the binder, until the desired form is achieved.

Material Extrusion

In this method, the structural material is heated as it passes through a nozzle, and is then deposited in layers to construct the model. The nozzle moves from side to side, and a platform shifts vertically to the level of each new layer.

Powder Bed Fusion

Powder Bed Fusion uses heat energy directed at specified zones of a powdered material, to melt or fuse the powder into a desired shape. It’s a relatively simple and cost-effective process that is suitable for the fabrication of production components. Selective laser sintering (SLS) is an additive methodology in this category.

Sheet Lamination

In sheet lamination, the bonding of thin layers or sheets of material builds up three-dimensional objects. One of the sheet lamination variants is ultrasonic additive manufacturing (UAM). Here, physical pressure and ultrasonic waves bond metal sheets at room temperature. Another variant is laminated object manufacturing (LOM), where a coat of adhesive substances is the bonding agent.

Directed Energy Deposition (DED)

Directed Energy Deposition or DED is a complex process often employed in repairing existing components, or for adding extra material to them. The materials used in DED are heated to melting point as they are deposited, which fuses them together. Laser engineered net shaping (LENS) and directed light fabrication (DLF) are innovative processes in this category.

A wide and diverse mix of materials may be joined or manipulated using the various types of additive manufacturing technologies. These range from more traditional fabrication materials such as plastics, metals, and ceramics, to foodstuffs and human tissue.

Use of Manufacturing Technology

Broadly speaking, investing in and implementing manufacturing technologies can increase the efficiency of business systems, and streamline an organization’s relationships with suppliers and customers. Manufacturing technology can also greatly increase the speed, flexibility, and efficiency of the production process, in addition to expanding the range of what can be produced.

These benefits aren’t confined to traditional heavy industries, either. In wine production for example, technology is used to maximize product quality and reduce production costs. Technology plays a key role in manufacturing process decision making, while process technology has a direct influence on quality control and product cost.

The implementation of innovative technologies can improve the way that businesses in the manufacturing sector operate. The use of technology in manufacturing has been proving beneficial since the days of the first Industrial Revolution. Today, the digitization of manufacturing is ushering in the Fourth Industrial Revolution, or Industry 4.0 — an age driven by data, connectivity, and cyber-physical systems.

In this environment, technology in manufacturing is facilitating a number of changes for the better, such as:

- Resource management software capable of coordinating the production process.

- Accounting systems that can link order books with production, dispatch, invoice generation, and stock replenishment systems.

- Streamlined warehousing, stock control, and inventory management systems.

- Online procurement and supply chain management software that lowers costs and facilitates a “just-in-time approach” to production.

Catalysts For Change

Historically, many changes in the manufacturing industry have originated from consumer demand, and the current drive towards technological advancement is no exception. Today’s consumers want the latest and greatest things — faster, better, personalized, and unique. And manufacturers are increasingly turning to technology, to meet these demands.

Many of the building blocks of Industry 4.0 are providing manufacturers with the tools and techniques they require to adapt to changing market conditions and patterns of customer behavior. They include:

Cloud services: Online platforms and service offerings enable organizations to quickly share data and resources from any location.

The Internet of Things (IoT): Smart connectivity is enabling the maintenance and monitoring of devices used in manufacturing processes.

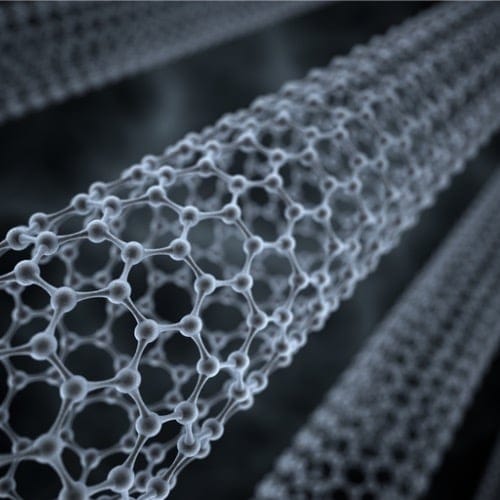

Nanotechnology: This emerging field is enabling faster computer processing, longer product life-cycles, super-precise manufacturing techniques, and pioneering advancements in sectors such as space engineering and biotechnology.

Nanotechnology: This emerging field is enabling faster computer processing, longer product life-cycles, super-precise manufacturing techniques, and pioneering advancements in sectors such as space engineering and biotechnology.

Advanced data analytics: Big data and predictive and prescriptive analytics technologies are facilitating and improving process control, the early detection of defects, preventative maintenance, and quicker response times for manufacturing.

Artificial intelligence (AI) and industrial robotics: AI, robotics, and related technologies are providing new ways to increase productivity, improve quality, and reduce costs by automating difficult or repetitive tasks.

Simulation technologies: Augmented reality (AR) and virtual reality (VR) in conjunction with analytics and machine learning systems are processing real-time data and mirroring the physical world in virtual models that can include machines, products, and humans.

Additive manufacturing: Technologies like 3D printing now make it possible to create almost any component using metal, plastic, and other materials, reducing lead times and streamlining the design-to-production process.

Horizontal and vertical system integration: These integrations are enabling companies, departments and functions to become much more cohesive, effectively transforming them into automated value chains.

Importance of Manufacturing Technology

In the digital economy, fast-growing manufacturers tend to be those who are more technology-oriented. Due to the importance of technology in manufacturing industry applications, organizations that embrace manufacturing technology are able to substantially increase productivity and efficiency within their operations, reduce costs and wastage, and ultimately, increase their bottom line.

The Role Of Technology In Industry

Across the board, technologies such as automation, robotics, data exchange, cloud computing, and artificial intelligence are becoming more mainstream. And at this point in the development of the Fourth Industrial Revolution (“Industry 4.0), many of the different technological innovations within the manufacturing sector are starting to converge. As this happens, more and more organizations are looking at how they can integrate new systems and implement them into their workflows.

Across the board, technologies such as automation, robotics, data exchange, cloud computing, and artificial intelligence are becoming more mainstream. And at this point in the development of the Fourth Industrial Revolution (“Industry 4.0), many of the different technological innovations within the manufacturing sector are starting to converge. As this happens, more and more organizations are looking at how they can integrate new systems and implement them into their workflows.

Though some have concerns that the increasing prevalence of robotics and automation could have a damaging effect on employment, for now at least, the expansion in the use of manufacturing technology is not reducing the need for human input and lowering the number of jobs. Instead, it is fueling a need for specialist workers and technicians, and creating more roles for innovative, forward-thinking manufacturers to help propel the industry into a new age of increased output.

Factors Fueling Progress

One of the key aspects of the importance of technology in manufacturing today is the influence of automation. Thanks to pre-configuration and robotic process automation, manufacturers around the world can leave repetitive, tedious and time-consuming tasks for technology to handle. Technologies like collaborative robots (cobots) are relieving some of the burden and risk from human manufacturing workers, while enabling organizations to enjoy increased productivity, improved quality, and greater efficiency in their manufacturing operations.

Speed, quality, and precision are major factors in differentiating successful manufacturers from the rest of the market. Computerized production planning systems are reducing the risk of error in many cases, and ensuring that quality products are supplied to consumers. Coupled with predictive analytics, artificial intelligence and machine learning systems are capable of producing automated workflows that employ collaborative robots to improve the quality of the manufacturing process and of overall production.

Productivity increases are also being facilitated, with manufacturing technologies enabling factories to run 24 hours a day and seven days a week — often year round. Automated systems can enable more to be done in a short time frame, with advanced automation and digital technologies contributing to greater precision and levels of quality.

Technologies Enhancing Production

Innovative techniques and uses of material are central to the importance of technology in production. In this respect, additive manufacturing — the category of technologies that includes 3D printing — is gaining momentum. Additive processes enable manufacturers to produce custom components to precise specifications, with minimum wastage. As the technology becomes more affordable, this is making it easier for inventors, innovators, and smaller companies to design and produce detailed components quickly and cost-effectively, and to market them on a global scale.

“Smart” manufacturing harnesses the power of the Industrial Internet of Things (IIoT) to populate manufacturing facilities with machines that can communicate with each other and work together to reduce downtime, minimize errors, and improve quality, while lowering labor, waste, and production costs.

IoT devices can also collect, process and analyze data, manage equipment, regulate maintenance schedules, track inventory, and measure performance. Using smart technology in combination with advanced analytics, organizations can monitor their entire manufacturing workflow, troubleshoot production issues, optimize performance, and gain insights for making business decisions — all in real or near-real time.

Artificial intelligence (AI) is playing a role in all of this, with algorithms capable of teaching machines to make complex decisions regarding custom product configurations, quality control, predictive or adaptive equipment maintenance, and other functions.

Predictive analytics with big data also opens opportunities for manufacturing organizations to make predictions and forecasts for future demand for goods, trends in customer behavior, and other market factors. This can enable manufacturers to judge when to produce their products to maximize profits, and which industry trends to follow, as they are just beginning to develop.

Though the technology is still evolving, blockchain provides manufacturers with the potential to create smarter supply chains capable of tracking every detail of a product’s journey, recording precise audit trails, and providing real-time visibility.

Advantages of manufacturing technology

Technologies like additive manufacturing, autonomous robots, Computer Numerical Control, and Integrated Computational Materials Engineering are radically altering the industrial landscape, enabling manufacturers to guarantee better control over the production process and ensure efficient production standards.

Advantages of manufacturing technology which are making this possible include:

Increasing Quality Levels

With robotics and automation now playing a substantial role in the manufacturing process, there’s less chance of human error and omissions that can lead to product defects or degradation. So one of the major benefits of advanced manufacturing technology is quality enhancement.

Greater Flexibility

Advanced manufacturing technologies may be applied to a diverse range of production scenarios, giving manufacturers greater flexibility in planning and executing their operations. Manufacturers can make products in small batches for niche customers, adjust their production lines in response to design changes, and reduce the time to market by generating prototypes quickly using technologies like 3D printing.

Increases In Productivity

Automated assembly and machines for mass fabrication enable manufacturers to increase their production output to levels previously unattainable with purely human labor. Automation technologies can also free workers to concentrate on higher level, strategic tasks that require decision-making.

Reducing The Time To Innovate

Technologies like Computer-Aided Design (CAD) and virtual modeling enable industrial designers to quickly create and modify plans for components or finished parts. These techniques are often more cost-effective than conventional manufacturing design and testing processes. Use of advanced technologies also enables manufacturers to produce high-quality goods that can be custom made specifically to a buyer’s requirements.

Enhanced Strategic Planning

Digital manufacturing systems using virtualization enable manufacturers to generate digital factories that can simulate the entire production process. This allows engineers to save money and time by optimizing factory layouts, identifying flaws in the production sequence, and modeling product output and quality.

Using design and process simulation, companies can try out many “what if” scenarios at minimal cost to validate their processes and arrive at the most optimum solutions. For organizations planning for expansion, digital simulations can provide a cost-effective pathway for manufacturers to replicate entire assembly lines in different locations.

Improved Safety

Human ergonomic simulation helps organizations to identify the best ways of carrying out a task manually, so as to cause the minimum possible physical stress to people working on the shop floor. This reduces the chance of accidents and occupational hazards.

Factories employing robotic automation or collaborative robots (cobots) to work alongside humans also gain the advantage of delegating hazardous or physically demanding tasks to these machines, rather than risking the health and safety of their human workforce.

The Benefits Of Additive Manufacturing

While much has been made in the media about the promise of 3D printing and other related technologies, some companies remain on the fence about additive manufacturing, and aren’t convinced that it’s the future. However, the advantages of additive manufacturing technology are quite numerous. They include the following:

A More Affordable Cost Of Entry

For some time, the cost of the machinery required for additive manufacturing has been too expensive for smaller manufacturers to contemplate. However, the development of new technologies has made the cost of entry much more affordable, with equipment costs now as low as $3,500 for a reliable industrial quality machine.

Another of the advantages of additive manufacturing is its capacity to reduce the amount of capital required for scaling up production without making major changes, giving manufacturers the benefit of both greater cost-effectiveness and agility.

Greater Design Freedom

In traditional manufacturing, modifying a design during production can lead to significant cost increases or time delays, as the tooling on a production line is changed out. Additive manufacturing gives engineers the creative freedom to produce multiple versions of a single design in a quick and cost-effective manner.

In traditional manufacturing, modifying a design during production can lead to significant cost increases or time delays, as the tooling on a production line is changed out. Additive manufacturing gives engineers the creative freedom to produce multiple versions of a single design in a quick and cost-effective manner.

Reduced Waste

Traditional manufacturing methods tend to generate a lot of material wastage. A milling machine for example works by removing material from a block that is bigger than the final product — material that’s typically in a form that cannot be reused.

Additive manufacturing benefits fabricators by significantly reducing the amount of waste and surplus material. Rather than removing material, the technology adds ingredients layer by layer so that only the material specifically required gets used. As a result, additive manufacturing can reduce material costs and waste by as much as 90%.

Less Energy Consumption

The fact that additive manufacturing uses less material produces an overall reduction in energy costs for the enterprise. The technology also generates savings by eliminating steps in the production process that would otherwise consume energy and resources.

In addition, the re-manufacturing of parts through additive manufacturing processes can return end-of-life products to a “like new” condition, using only 2% to 25% of the energy that it would take to build an entirely new part.

Product Customization

Additive manufacturing gives fabricators the opportunity to offer a “made to order” service, customizing designs for individual clients. For example, 3D printing is employed in creating items tailored for specific needs, and with short production runs, in sectors including the oil and gas, food and beverage, pharmaceutical, and automotive industries.

Rapid Prototyping

Prior to final production, additive manufacturing enables organizations to produce several prototypes, honing a design and reducing the room for error. As we have already observed, changes to the original specification can be made digitally, reducing the expense associated with traditional design modifications.

Prior to final production, additive manufacturing enables organizations to produce several prototypes, honing a design and reducing the room for error. As we have already observed, changes to the original specification can be made digitally, reducing the expense associated with traditional design modifications.

Training And Skills Acquisition

Unlike in the early stages of the technology’s development, there is now a wide variety of training programs on offer for additive manufacturing designers and fabricators. Courses run from novice to advanced levels, and include training on the tools and technology of additive manufacturing, methods and best practices for using the technologies, and instruction on material handling and post-production processes.

History of Manufacturing Technology

Before the advent of heavy machinery and automation, manufacturing was done by hand. Most of these skilled trades were performed in a rural setting, with knowledge being passed down from master craftsmen to apprentices.

As demand for craft goods grew, putting-out systems were introduced to unite a collective of manufacturers under a single business hub — a central provider who was able to subcontract specific orders to rural manufacturers, spreading the workload, and giving them a wider customer base.

With the evolution of manufacturing technology in the subsequent centuries, the development of interchangeable parts led to more efficient usage of labor, and mass production. The refinement of fixtures, jigs, and gauges paved the way for identical parts to be manufactured quickly, before being passed along to less-skilled assembly workers.

Manufacturing Technology Timeline

Key events in the history of manufacturing technology include:

Important Developments In Manufacturing Engineering

Manufacturing Engineers focus on the design and operation of integrated systems for the production of high-quality, economically competitive products. These systems may include computer networks, robots, machine tools, and materials-handling equipment.

Regarding the history of manufacturing engineering, most historians credit Matthew Boulton’s Soho Manufactory (opened in 1761) as the first true manufacturing facility, which laid the groundwork for modern-day manufacturing engineering. Among historians, the general consensus is that manufacturing engineering came to light in the mid-18th century.

Cotton mills used inventions such as the steam engine and power loom during the 19th century, and at this time, precision machine tools and replaceable parts facilitated improved production efficiency with less waste. This established the underlying principles basis for later studies of manufacturing engineering.

The Evolution Of Additive Manufacturing

As far back as the 1800s, ideas surrounding 3D scanning were beginning to take shape. Key events in the history of additive manufacturing include:

Future of Manufacturing Technology

The global manufacturing market involves itself in processing and producing a wide range of items, in a spectrum that spans consumer goods, heavy industrial outputs, the storage and transportation of raw materials, and the distribution and sale of finished products. To sustain growth, manufacturers are currently focusing on three key areas.

The first is to improve the rate at which expensive fixed assets are utilized. Second is filling the current and anticipated shortages of specialized labor. In their Future of Manufacturing Technology projections, some analysts estimate that by 2028, the skills gap in the US will result in 2.4 million vacant positions, out of a total 16 million manufacturing jobs. Thirdly, manufacturers must protect operating profits as industry average margins continue to decline.

Many startups are now offering custom-designed products and services to help traditional manufacturers meet these goals. In this regard, six key themes are now emerging in manufacturing technology:

Robotics: auto-guided vehicles, sorting arms

Robotics: auto-guided vehicles, sorting arms- Software as a Service (SaaS): especially vision software, and predictive maintenance

- Digitization / data software: These include data analytics and marketplaces solutions.

- Augmented reality / virtual reality (AR/VR): wearable headsets, vision picking software

- Material science: additive manufacturing, and the development and use of innovative materials

- Batteries: contactless charging systems, ultrasound transmitters

Looking forward, robotics and SaaS, stand out as the most disruptive technologies likely to have a high impact on manufacturing — and two areas that will create the most value for manufacturers by universally addressing the most significant challenges facing the industry, such as the talent shortage, optimizing throughput rates, and machine utilization.

Additive Manufacturing In Focus

Additive manufacturing is currently going mainstream, as technology prices fall and researchers develop new materials for use with additive systems, new manufacturing processes, and new systems with greater adaptability.

Looking toward the future of additive manufacturing, the technology looks set to play a continuing role in complementing traditional manufacturing processes, or in some cases, replacing them entirely.

Additive manufacturing systems and unique materials will facilitate a broader range of vertical applications. The future of additive manufacturing in engineering will likely be unlocked through the development of new materials which are versatile enough to be used with a broader range of commercial additive manufacturing systems.

The newer systems and broader range of materials being developed will also help increase throughput with additive manufacturing systems, improving productivity, printing resolution, build volumes, and loading / unloading procedures.

Examples of Manufacturing Technology

Artificial intelligence (AI), the Internet of Things (IoT), robotics, 3D printing, and virtual reality (VR) are some typical examples of manufacturing technology. Others include:

Smart Manufacturing

Smart manufacturing makes both information and manufacturing procedures available on demand, so that it’s possible to use analytics to make decisions regarding the course of any critical business operation, and computer integrated manufacturing techniques and mechanisms to put these decisions into action.

Cloud Computing

Cloud computing enables manufacturers to use a network of remote services and tools which are connected via the internet, along with various facilities and resources for storing, managing and processing information. So for example, cloud-based Software as a Service (SaaS) can make Enterprise Resource Planning (ERP) platforms available to businesses without the resources or skills to deploy them on-site.

Nanotechnology

Though still in its early stages of development, nanotechnology is currently being used in the biotechnology and space engineering sectors. At a technical level, it enables faster computer processing, and smaller memory cards with more memory space. Nanotechnology is also the basis for garments that last longer and help keep the wearer cool during summer, and bandages that are able to heal wounds more quickly.

Production Technology

Here are 5 examples of production technology:

Additive Manufacturing

A class of technologies most commonly associated with 3D printing, additive manufacturing consists of several techniques for making products and components by depositing thin layers of material using a digital blueprint.

Nanomanufacturing

This is manufacturing which occurs at the atomic level. It can be either top-down (reducing larger materials down to nano scale) or bottom-up (building things from molecular components).

Self-Assembling Components

This is a process by which components interact with each other spontaneously to build an ordered structure.

Biomanufacturing

This is the process of producing products out of biological materials, such as pharmaceuticals, chemicals, paper, and food.

Robotics

With advances in machine learning and predictive analytics, manufacturers are finding it more cost-effective to move production facilities with industrial robots closer to consumers.

Flexible Manufacturing

Flexible manufacturing typically involves a network of interconnected processing workstations with computer terminals that process the end-to-end creation of a product. A flexible manufacturing system example would have connections ranging from loading / unloading functions, to machining and assembly, to storing, to quality testing, and data processing.

Here are 5 examples of flexible manufacturing:

- A flexible manufacturing system (FMS) for forging metal parts would typically have four or more production machines with computer control modules with systems to produce, process, assemble, weld, and forge the metal.

- Organizations can use an FMS to simulate a production line, for training and education. This allows students to become familiar with the equipment and duties of working in a modern manufacturing facility.

- A flexible manufacturing system can aid consumer goods manufacturers in improving inventory control, through the integration of part tracking and production planning systems.

- For auto parts manufacturers, an FMS can help in reducing production bottlenecks, such as those affecting the flow of materials. Systems can enable the factory to integrate assembly, testing, inspection, and packaging in one uninterrupted line.

- Manufacturers of oil and gas equipment can streamline their inventory and optimize their lines of supply with value chain partners, using a flexible manufacturing system. This can enable them to order only the materials they actually need, have them delivered directly to the workshop where the parts will have to be assembled, and store the parts at POU (point of use) inside the workshop.

People Also Asked

What are the disadvantages of additive manufacturing?

Considerable capital expenditure is required to purchase the equipment necessary to support additive manufacturing. And since the raw materials required for the process must often consist of very fine particles, the cost of these powders can further inflate the budget.

Since there’s usually no way to successfully introduce additional materials and traits later in the 3D printing process, additive manufacturing is unsuitable for components requiring alloys.

Additive manufacturing technology is still evolving, and current iterations are often too slow for economical mass production.

What is an example of additive manufacturing?

Spirit AeroSystems uses 3D printing to produce near-net-shape aerospace components for the Boeing 787. Used for access door latch fittings on the passenger jets, 3D printing this component to near-net shape before machining offers a lower buy-to-fly ratio than machining the part directly from stock materials.

What are the types of additive manufacturing?

The International Organization for Standardization (ISO/ASTM 52900) classifies seven types of additive manufacturing technology:

- Vat photopolymerization: Also known as stereolithography (SLA), the process whereby a liquid is cured by a light source, turning it into a solid.

- Material extrusion: An umbrella term for all additive manufacturing processes in which material is dispensed through a nozzle to form shapes.

- Sheet lamination: A process in which sheets of material are bonded together layer by layer, to form a 3D object.

- Powder bed fusion: The use of a thermal energy source to fuse specific areas of powdered material.

- Binder jetting: These processes use a bonding agent to join powdered materials together.

- Material jetting: Here, droplets of build material are selectively deposited and cured to form a part.

- Directed energy deposition (DED): These processes fuse materials by melting them as they’re being deposited.

How did technology help industry?

The internet is now an important part of any business — and manufacturing is no exception. The web and cloud provide access to information, tools, platforms, and services that benefit industry. Speed is also critical in today’s business world, and thanks to digital technology, many processes can be conducted in real or near real time.

The internet is now an important part of any business — and manufacturing is no exception. The web and cloud provide access to information, tools, platforms, and services that benefit industry. Speed is also critical in today’s business world, and thanks to digital technology, many processes can be conducted in real or near real time.

A wide range of technologies are having a positive impact on manufacturing. Computer software, big data analytics, fiber optics, drones, image recognition, artificial intelligence (AI), virtual reality (VR) and other technologies play a big role in different industrial sectors.

What are some manufacturing skills?

Within the next decade, analysts expect 2.2 million jobs in advanced manufacturing to go unfilled due to a lack of adequately trained labor. Among the skills necessary for a career in advance manufacturing are:

- Computer literacy / Digital fluency

- The ability to write and understand code

- Ability to program specific manufacturing devices and machines

- Experience in machining, fabricating, and complex assembly

- Big data analytics skills

- Cyber security expertise

- Problem-solving capability

- Communication, collaboration, and change management skills

- Soft skills

Is manufacturing a good career?

The short answer is “Yes.” In the current economy, jobs in manufacturing are in plentiful supply, use the latest technology, provide an opportunity for growth, and are secure.

Manufacturers contribute over $2.3 trillion to the economy of the United States every quarter, and the US currently has 12.85 million manufacturing jobs, or around 8.5% of the workforce. On average, American manufacturing employees earn nearly 30% more than workers in other industries — including pay and benefits.

What is the biggest manufacturing company?

As of November 2020, the Volkswagen Group in Germany is the world’s biggest manufacturing company, with an annual revenue of around $282.9 billion. In second position is Toyota Group Engineering of Japan, with an estimated yearly revenue of $265.1 billion.

Among the top ten largest manufacturing companies in the world are organizations from the automotive industry, and sectors including electronics, medical, and technology. China currently leads the world in terms of manufacturing production, with over $2.01 trillion in output.